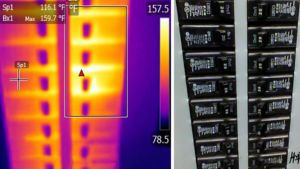

This image shows yellow for hotter temperatures, black for colder temperatures. The thermal pattern indicates that the breakers have connection issues at the back of the panel. On the surface, they looked like any other circuit breakers. But inside, invisible to the human eye, was a hidden danger. The breakers were smoldering at 159.7 degrees.

They looked just like any other circuit breakers: a set of electrical devices mounted in a steel box. But inside, invisible to the human eye, was a hidden danger. The breakers were smoldering at 159.7 degrees. Thermography made the danger visible.

Using a thermal imaging camera, inspectors were able to “see” the heat so that the hidden wiring issue could be corrected. Without a repair, the problem could have resulted in an electrical fire – a leading cause of building fires.

Just as photography means “writing with light,” thermography means “writing with heat.” A thermal camera captures infrared images of electrical components, revealing hidden defects that the eye cannot detect.

Cincinnati Insurance loss control consultants are trained to use thermal cameras as a part of value-added services they provide when visiting customer locations. Identifying electrical faults early can reduce the likelihood of a fire. In addition to the cost of a fire loss and its effect on insurance, a business could experience downtime, loss of reputation or even employee injury. Even if an identified problem would not result in a fire loss, being alerted to potential issues can help a business balance the electrical load, increasing efficiency and potentially saving money.

After touring a facility and imaging a suspected issue, the loss control representative alerts the business owner, providing infrared photos of the potential problem. The business owner then engages a licensed electrician to correct the problem, thus avoiding a potential fire.

Some important things to know when using thermography:

- The age of your electrical system does not guarantee trouble-free operation. Electrical issues are found in new construction as well as old, so thermography can be an effective tool even with newer systems.

- More than 25% of workplace fires can be linked to electrical systems.

- If thermography reveals a problem, a qualified, licensed electrician should be called to confirm issues and make repairs.

- Successful use of this technology requires the proper skillset and knowledge. All of Cincinnati’s loss control consultants have received classroom and hands-on training, learning the theory of thermography as well as the use of thermographic cameras.

Cincinnati business policyholders can request loss control services through their local, independent insurance agent.

About Cincinnati Loss Control: Loss control services help you minimize losses by identifying, evaluating and providing control measures. How your business controls losses can affect your productivity and the safety of your employees.The Cincinnati Insurance Company and your local independent agent representing Cincinnati provide high-quality, valuable loss control service as part of your insurance program as a complimentary service. Cincinnati’s knowledgeable and experienced staff members are always available when you need them because they live and work in your community.

—

This loss control information is advisory only. The author assumes no responsibility for management or control of loss control activities. Not all exposures are identified in this article. Contact your local, independent insurance agent for coverage advice and policy service.